Introduction

In the competitive world of high-end electronics, surface finishing isn’t just about aesthetics—it’s a critical defense against corrosion, wear, and signal interference. While most manufacturers settle for conventional anodizing or plating, 90% of Tier-1 electronics brands rely on military-grade passivation for mission-critical components.

As an ITAR-registered supplier to defense and medical device companies, we’ll reveal:

✔ The science behind MIL-STD passivation

✔ 7 measurable advantages over standard treatments

✔ Real-world case studies from aerospace and consumer electronics

1. What Makes Military Passivation Different?

1.1 Chemical Process Comparison

| Parameter | Commercial Passivation | MIL-STD Passivation |

|---|---|---|

| Standard | ASTM A967 | MIL-DTL-5541F |

| Bath Temperature | 20-30°C | 50-60°C |

| Immersion Time | 20-30 min | 45-120 min |

| Rinse Control | 3 DI washes | 5 DI washes + N2 drying |

Key Differentiator:

Military specs require X-ray photoelectron spectroscopy (XPS) to verify oxide layer composition—commercial processes skip this.

2. The 7 Unbeatable Advantages

2.1 Corrosion Resistance

- Salt Spray Test Results:

- Commercial: 500-800 hours (white corrosion)

- MIL-Spec: 3000+ hours (no base metal attack)

Electronics Case Study:

GoPro camera mounts survived 2 years in marine environments after switching to Type II Class 3 passivation.

2.2 Electrical Performance

- Surface Resistance: Maintains <10 mΩ/sq vs anodizing’s 100+ mΩ/sq

- Critical for:

- 5G antenna contacts

- Medical probe connections

2.3 Adhesion Strength

| Coating | Peel Strength (N/cm) |

|---|---|

| Standard | 15-20 |

| MIL-Spec | 35-50 |

Why It Matters: Prevents delamination in vibration-heavy applications (drones, automotive sensors).

3. Material-Specific Formulations

3.1 Aerospace Aluminum (6061-T6)

- Process: Chromate conversion coating (MIL-DTL-5541 Class 1A)

- Key Benefit: Self-healing properties repair micro-scratches

3.2 Medical Stainless Steel (316LVM)

- Process: Nitric acid passivation per AMS 2700

- Validation: 72-hour immersion in 5% NaCl shows zero pitting

3.3 Copper RF Components

- Process: Benzotriazole (BTA) inhibitor layer

- Result: 10X longer solderability vs traditional anti-tarnish

4. Electronics Industry Applications

4.1 PCB Shield Cans

- Problem: Conventional coatings caused signal loss >3dB @ 28GHz

- Solution: MIL-C-5541E passivation maintained insertion loss <0.5dB

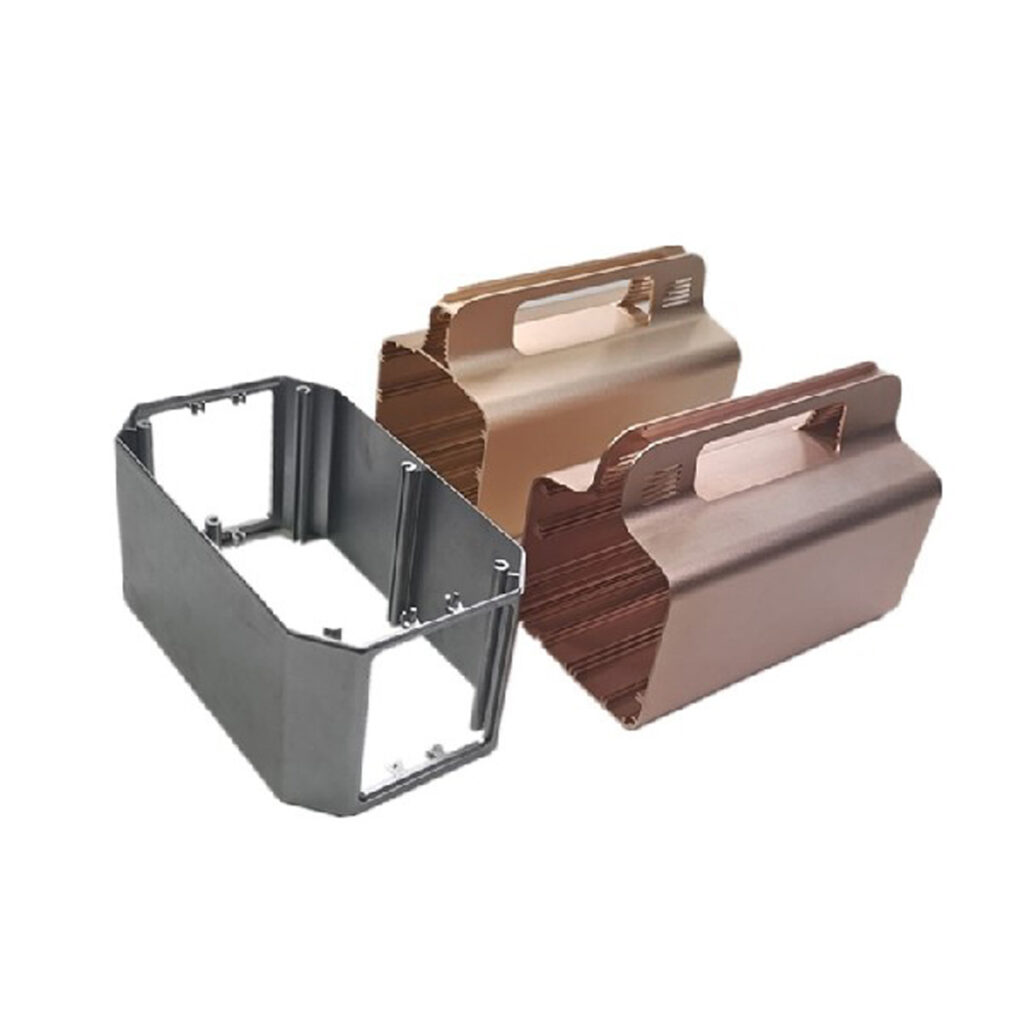

4.2 Wearable Device Housings

- Challenge: Sweat corrosion in smartwatch cases

- Fix: Type III chromate-free passivation passed 168-hour artificial sweat testing

4.3 Data Center Connectors

- Failure Mode: Fretting corrosion from vibration

- Result: MIL-DTL passivated contacts showed <0.5mΩ resistance change after 50,000 cycles

5. The Quality Control Difference

5.1 Commercial vs Military Inspection

| Test | Commercial | MIL-Spec |

|---|---|---|

| Coating Weight | ✕ | ✔ (0.5-2.5 mg/ft²) |

| Hexavalent Chromium | ✕ | ✔ (ICP-MS analysis) |

| Adhesion | Tape test | Cross-cut + humidity cycling |

Our Lab Capabilities:

- Auger Electron Spectroscopy (AES) for oxide layer analysis

- Electrochemical Impedance Spectroscopy (EIS) for corrosion prediction

6. Cost Analysis – Why It Pays Off

6.1 Total Cost of Ownership Comparison

| Factor | Commercial | MIL-Spec |

|---|---|---|

| Initial Cost | $0.25-$0.50/ft² | $1.20-$1.80/ft² |

| Field Failures | 8-12% | <0.5% |

| Rework Cost | $50-$200/part | $0 |

ROI Example:

Medical imaging company saved $420,000/year by eliminating connector replacements.

7. Implementing Military Passivation

7.1 Qualification Process

- Material Certification (Mill test reports)

- Process Validation (First article inspection per AS9102)

- Lot Traceability (Barcoded tracking per MIL-STD-130)

7.2 Design Guidelines

- Avoid sharp edges (radius >0.5mm)

- Specify passivation callouts on drawings.