Introduction

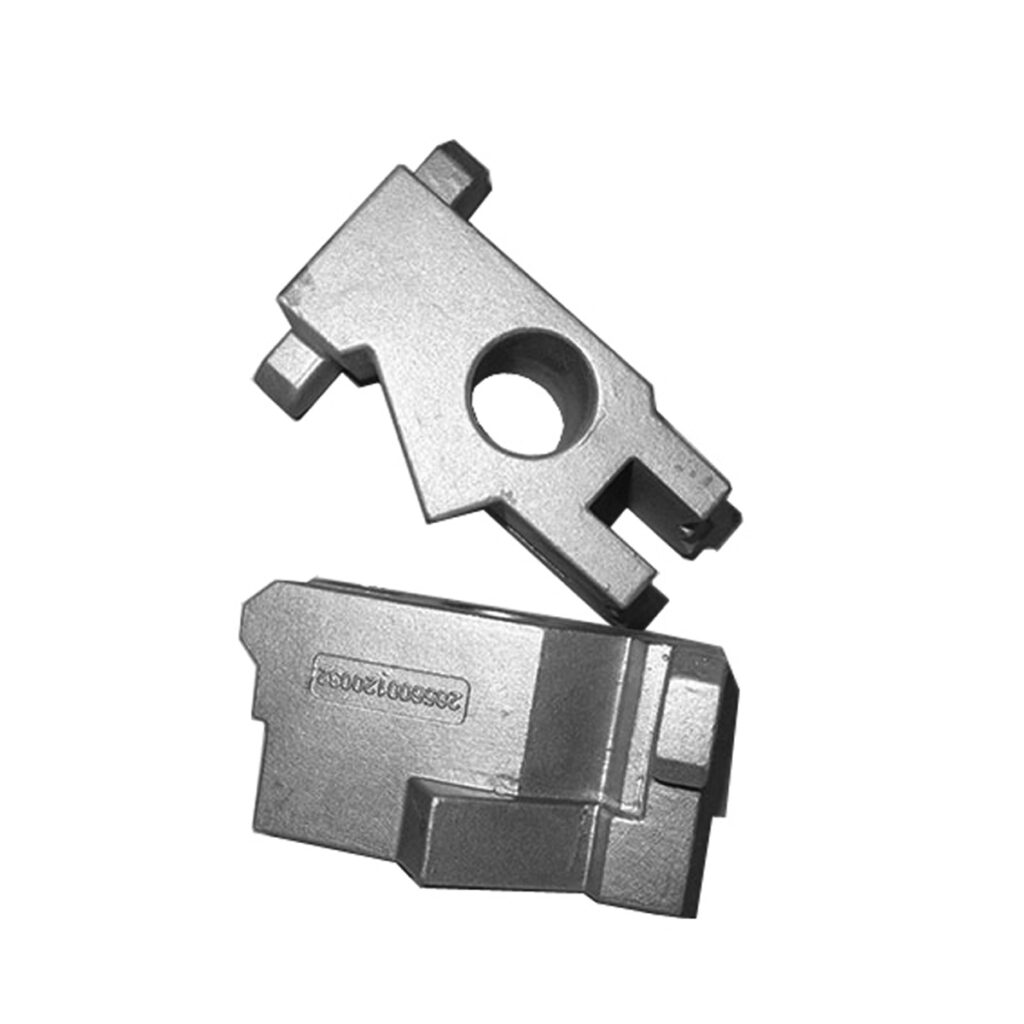

The fusion of Computer Numerical Control (CNC) machining and Investment Casting (IC) has revolutionized precision manufacturing, enabling seamless digital workflows from wax pattern creation to final machined components. This synergy bridges the gap between complex near-net-shape casting and high-precision machining, optimizing efficiency, accuracy, and cost-effectiveness.

This comprehensive guide explores the end-to-end digital workflow integrating CAD/CAM, CNC machining, and investment casting, with actionable strategies for manufacturers in the aerospace, medical, and automotive industries.

1. The Digital Workflow: From CAD to Finished Part

1.1 Step 1: CAD Design & Simulation

- 3D Modeling: Engineers design the part in CAD software (e.g., SolidWorks, CATIA), optimizing geometry for both casting and machining.

- Simulation: Casting simulation tools (e.g., MAGMASOFT, ProCAST) predict defects like shrinkage or porosity before production.

- Design for Manufacturing (DFM):

- Minimize machining stock with near-net-shape casting.

- Avoid sharp corners and thin walls to reduce casting stresses.

1.2 Step 2: Wax Pattern Production

- Traditional Injection Molding: Wax injected into aluminum molds (suitable for high-volume production).

- 3D Printing (Additive Manufacturing):

- SLA/DLP: High-resolution wax-like resins for rapid prototyping.

- PolyJet: Multi-material wax patterns with soluble supports.

- Binder Jetting: Sand-like molds for direct metal casting.

1.3 Step 3: Investment Casting Process

- Shell Building:

- Traditional: Ceramic slurry + stucco (6–8 layers).

- Silica Sol: Fewer layers, superior surface finish.

- Dewaxing & Firing: Steam autoclave or flash firing removes wax.

- Metal Pouring: Vacuum or gravity casting ensures defect-free fills.

1.4 Step 4: CNC Machining of Castings

- Fixturing: Custom jigs align castings for machining critical features.

- CAM Programming:

- Adaptive toolpaths reduce cycle time (e.g., trochoidal milling).

- High-speed machining (HSM) for hard alloys (Inconel, Ti-6Al-4V).

- Post-Machining Inspection: CMM or laser scanning verifies tolerances.

2. Key Advantages of CNC + IC Integration

| Benefit | Explanation |

|---|---|

| Reduced Material Waste | Near-net-shape casting minimizes CNC stock removal. |

| Faster Lead Times | Digital workflows eliminate manual pattern-making bottlenecks. |

| Higher Accuracy | CNC machining ensures critical features meet tight tolerances (±0.001″). |

| Complex Geometry Support | IC handles intricate internal passages; CNC adds precision threads/flanges. |

| Cost Efficiency | Lower machining hours + optimized material usage = 15–30% cost savings. |

3. CAD/CAM Integration Strategies

3.1 Unified Software Platforms

- Siemens NX: End-to-end CAD/CAM/CAE for casting and machining.

- Autodesk Fusion 360: Cloud-based CAM with generative design for IC.

- PTC Creo: Parametric modeling + CNC toolpath integration.

3.2 Hybrid Manufacturing (Additive + Subtractive)

- 3D-Printed Wax Patterns: Direct digital workflow from CAD to casting.

- CNC Hybrid Machines: Mill-printed metal castings in one setup (e.g., DMG Mori Lasertec).

3.3 Digital Twin & Process Optimization

- Virtual Prototyping: Simulate casting solidification and machining stresses.

- AI-Driven CAM: Tools like SwarfCAM optimize feeds/speeds for cast alloys.

4. Industry Applications

4.1 Aerospace

- Turbine Blades: IC creates cooling channels; CNC machines mounting interfaces.

- Brackets: Thin-wall casting + lightweight machining for fuel efficiency.

4.2 Medical

- Implants: Titanium castings with CNC-polished biocompatible surfaces.

- Surgical Tools: Stainless steel castings + EDM-machined sharp edges.

4.3 Automotive

- E-Vehicle Components: Aluminum housings (IC) with CNC-tapped bolt holes.

- Transmission Gears: Net-shape steel casting + gear tooth grinding.

5. Overcoming Challenges

5.1 Dimensional Variability in Castings

- Solution: Use CNC probing to adjust toolpaths in real time.

5.2 Hard Material Machining

- Solution: Diamond-coated tools for nickel alloys; cryogenic cooling.

5.3 Cost Control

- Solution: Automate CAM programming with feature-based machining.

6. Future Trends

- AI-Powered Defect Prediction: Machine learning identifies casting flaws pre-machining.

- Blockchain Traceability: Secure digital threads from CAD to the final part.

- Sustainable Practices: Recyclable waxes + energy-efficient CNC.

7. Conclusion

The CNC + IC digital workflow represents the future of precision manufacturing, combining the design freedom of investment casting with the accuracy of CNC machining. By adopting integrated CAD/CAM strategies, manufacturers can achieve:

✅ Shorter time-to-market

✅ Lower production costs

✅ Unmatched quality

One Response

Ready to optimize your production chain? [Contact us] for a customized CAD-to-CNC solution!